While there are many die-cutting operations, some of which are very complex, they can all be reduced to the following simple fundamentals.

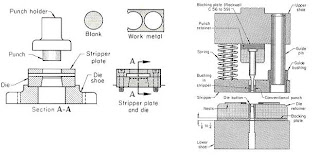

Fig. 4-1 Drop-through Blanking Die Fig. 4-2 Piercing Die Assembly

Fig. 4-1 Drop-through Blanking Die Fig. 4-2 Piercing Die Assembly4.1.1 Plain blanking: Fig. 4-1 shows a simple operation of this type. The material used is called the stock and is generally a ferrous or nonferrous strip. During the working stroke the punch goes through the material, and on the return stroke the material is lifted with the punch and is removed by the stripper plate. The stop pin is a gage for the operator. In practice, he feeds the stock by hand and locates the holes to be punched as shown. The part that is removed from the strip is always the work piece (blank) in a blanking operation.